Common Bulk Flour Storage Mistakes Manufacturers Must Avoid

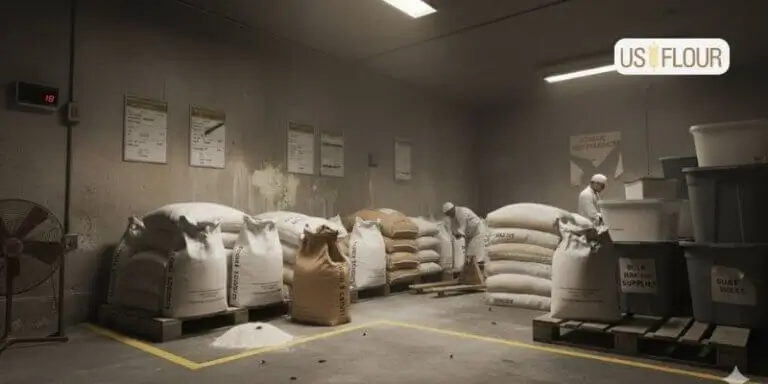

Smooth production lines can quickly run into trouble when flour is stored improperly. Bags stacked too close to walls, some opened or half-sealed, and missing labels may seem harmless at first, but these small oversights often lead to clumping, spoilage, pest problems, and costly waste. When dealing with large volumes, even minor storage mistakes can quietly compromise quality, consistency, and costs. The following outlines the most common bulk flour storage mistakes manufacturers make—and how to avoid them without overcomplicating operations.

Assuming Flour Lasts Forever

This is the most common mistake.

Flour isn’t something you store and forget about. It has a shelf life, and that shelf life depends heavily on how it’s handled once it arrives. Temperature changes, moisture in the air, and even light exposure all play a role.

Good bulk flour storage practices matter more than people think. If the storage environment isn’t stable, flour quality slowly declines, even if it still looks fine on the outside.

Letting Humidity Get Out of Control

Humidity is one of flour’s biggest enemies.

Too much moisture can lead to clumping, off smells, or spoilage. Sometimes it doesn’t show up until the flour hits production, and by then, the damage is done.

Many manufacturers assume general warehouse conditions are good enough. They’re not always. Flour needs a dry, well-ventilated space with humidity levels checked regularly.

Even if your flour arrives in perfect shape from a trusted bulk flour supplier, it’s your storage conditions that determine how long it stays that way.

Skipping Proper Inventory Rotation

First-in, first-out is simple in theory but often ignored. Older stock gets buried, new deliveries get stacked in front.

Clear labels, visible dates, and a simple rotation system go a long way. This isn’t just about freshness. It also helps with traceability if questions arise.

A reliable bulk flour distributor may give guidance on this, but it only works if it’s followed daily.

Storing Flour Too Close to Walls or Floors

This one seems harmless, but it causes real issues.

Flour stored directly on floors or pressed against walls is more exposed to moisture and pests. Condensation can form where you can’t easily see it. Over time, that creates problems.

Use pallets. Leave space around stacks. Make inspections easy. These minor adjustments protect your product without much effort.

This is one of those basic details of bulk flour storage that often gets overlooked until something goes wrong.

Mixing Different Flours Without Clear Separation

Not all flour behaves the same.

Bread flour, pastry flour, whole wheat, specialty blends. Each one has its own purpose and performance. Storing them together without clear labeling invites mistakes.

One wrong scoop can throw off an entire batch. And if allergens or specialty formulations are involved, the risks get even bigger.

If you handle a wide range of bulk baking supplies, clear separation isn’t optional. It’s essential.

Underestimating Pest Risks

Flour attracts pests. That’s just reality.

Even a small gap in storage practices can lead to contamination before anyone notices. When you start noticing the signs, it might be too late. You would begin dealing with downtime, disposal, and cleanup.

You can prevent all that by regularly inspecting, using large, sealed containers, and maintaining consistent sanitation routines. Pest prevention isn’t something you set up once and forget.

Strong bulk flour storage habits help keep this from becoming an expensive problem.

Relying Too Much on Packaging

Heavy-duty bags are helpful, but they’re not magic.

Once bags are opened, flour is exposed. If containers aren’t appropriately sealed or flour is left uncovered during transfers, moisture and odors can sneak in.

Packaging helps during shipping. Storage practices matter more once the flour is on-site, especially when you’re working with large quantities of bulk baking supplies.

Not Training Staff on Storage Basics

Even the best systems fail if staff don’t understand why rules exist. Quick refreshers, visual reminders, and clear guidelines build consistency and protect quality.

Outgrowing Your Storage Setup Without Adjusting

What worked when production was smaller may no longer work.

As volume increases, storage areas get tighter. Turnover speeds up. New flour is added. Without adjusting your setup, mistakes start creeping in.

Regularly reviewing storage needs helps you stay ahead of problems. This is where communication with your bulk flour supplier can be especially helpful as your operation grows.

Relying on Memory Instead of Written Procedures

“We’ve always done it this way” isn’t a system.

Written procedures remove guesswork. They help with training, audits, and daily consistency. When everyone knows precisely how flour should be received, stored, rotated, and handled, fewer mistakes happen.

Many manufacturers find it helpful to document recommendations from their bulk flour distributor and incorporate them into daily operations.

Not Checking Storage Conditions Regularly

Seasons change, equipment ages, and buildings shift. Regular walk-throughs to check for moisture, odors, damaged packaging, or clutter prevent small issues from becoming major problems.

Final Thoughts

Flour may be simple—but storing it properly takes intention. Most mistakes happen not from neglect but from assuming simplicity. Good storage is quiet, steady, and essential.

At US Flour, we work closely with manufacturers to ensure bulk flour arrives and stays in optimal condition. By combining best practices with reliable supply, you can focus on production, not storage headaches.

Power to The Bakers.

Power to The Bakers.